PLEase Call Me !

+91 90990 85037

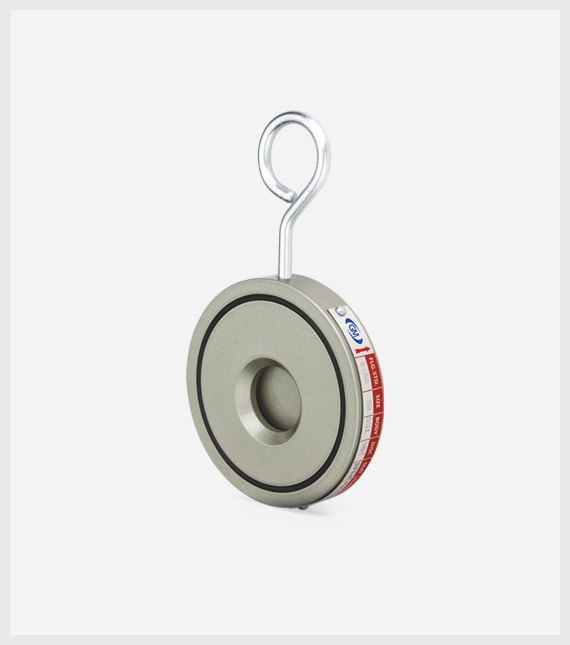

Secure Your Reverse Flow

Wafer Check Valve

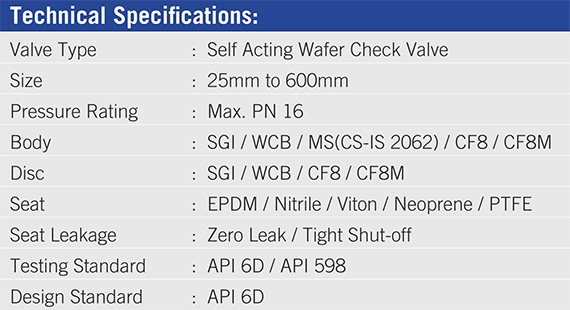

GMFPL's Single Wafer Check Valves are used in pipelines to prevent backflow of the fluid. The valves are manufactured according to API 6D standard and tested in accordance with API 598. These valves are fast acting in closing, thereby maximising protection to prevent or minimize the adverse effect of the back-flow. Opening and closing of the valve takes place at an extremely low pressure over the valve disc. The discv design enables the valve to open or close with a very low differential pressure which makes them ideal for services operating under low differential pressure. The pressure drop across the valve in fully open condition is relatively low and makes them ideal for pump discharge duties. The valves have a sturdy design, simple construction and are reliable in operations.

Wafer Check Valves have extremely short overall lengths in comparison with the standards flanged end Swing Check Valves as the face-to-face distance in these valves is extremely less. The Size and Weight are considerably reduced. This offers a great advantege for installation, handling, transportation and storing.